Polyimide Resin

Leading Manufacturers, Exporters, Wholesaler and Retailer of Abron MP 36 Polyimide Resin, Abron PIR 100 Polyimide Resin, Abron PIR 15 Polyimide Resin, Abron PIR 1800 Polyimide Resin, Abron PMR 7200 Polyimide Resin and Abron S10 Polyimide Resin from Hyderabad.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Color | Yellow |

| Grade | Industrial |

| Shelf Life | 1Year |

| Purity | 99% |

| Form | Powder |

| Soluable In Water | No |

| Type | Polyimide Resin |

| Brand Name | ABRON |

| Thickness | Powder Resin |

| Style | Raw |

| Packaging Size | 0-25Kg |

| Packaging Type | Plastic Drums |

| Application | Industrial Use |

| Appearance | Fine Yellow Powder |

| Bulk Density | 150 – 350 gm/1000cc* |

| Thermal Stability | 350 - 400°C |

| Particle Size | 80 – 325 Mesh |

| Size | Depending Upon the Particle Size |

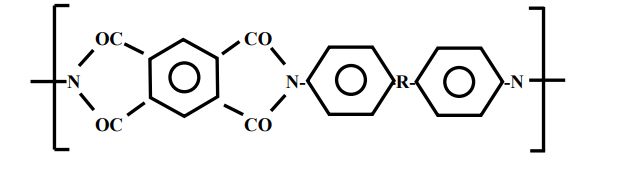

ABRON MP36 is a wholly imidised non meltable polyimide resin powder which can be molded by applying temperature & pressure. This polymer finds application in molding stock shapes, as a filler material in PTFE & as a binder resin for molding resin for bonded diamond grinding wheels.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Color | Yellow |

| Grade | Technical |

| Shelf Life | 1Year |

| Purity | Polyimide Resin |

| Form | Powder |

| Soluable In Water | No |

| Type | Polyimide Resin |

| Brand Name | ABRON |

| Thickness | Liquid Resin |

| Packaging Size | 0-25Kg |

| Packaging Type | Plastic Drums |

| Application | Composite Application |

| Melting Point | 220 - 250°C |

| Appearance | Pale Yellow to Orange Colour |

| State | Powder |

| Bulk Density | 0.5 – 0.8 gm/cc |

| Solubility | Insoluble in Most Solvents |

| Cure Temperature | 300°C |

| Particle Size | < 88 Microns |

ABRON PIR 100 is compatible with various types of fillers. The components prepared using ABRON PIR100 provide a Tg of 371 C and can withstand short time excursions upto 425 C.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Color | Yellow |

| Grade | Industrial |

| Shelf Life | 1 month at < 0 C |

| Purity | Liquid Polyimide Resin |

| Form | Liquid |

| Soluable In Water | No |

| Brand Name | ABRON |

| Thickness | Liquid Polyimide Resin |

| Style | Raw |

| Packaging Size | 0-25Kg |

| Packaging Type | Plastic Drums |

| Application | Industrial Use |

ABRON PIR-15 resin system has been developed for the manufacture of advanced composites for Space, Aerospace & Defense applications. This Polyimide based polymer can be used as a matrix material at temperatures upto 316°C continuous applications and short excursions upto 361°C. Of all the High Temperature materials this polyimide displays exceptional behavior in terms of processing properties, thermooxidative stability and retention of mechanical properties at temperatures in the 300°C– 316°C range.

The main applications of this resin system is in the manufacture of composites for aircraft industry for engine ducts, fan blades, inner cowls, swirl frames, nozzle flaps & fins and bodies of missiles, etc.

The resin system consists of three solutions ( 50 % solid loading in Methanol ) which have to be mixed ( under specific conditions and ratios ), before use. The resin can be used for making prepregs, filament winding or suitably modified for molding applications.

| Business Type | Manufacturer, Exporter |

| Download | |

| Country of Origin | India |

| Color | Brown |

| Grade | Industrial |

| Shelf Life | 1 Month at RT |

| Purity | Liquid Polyimide Resin |

| Form | Liquid |

| Soluable In Water | No |

| Type | Polyimide Resin |

| Brand Name | ABRON |

| Thickness | Liquid Polyimide Resin |

| Style | Raw |

| Packaging Size | 25-50Kg |

| Packaging Type | Plastic Drums |

| Application | Industrial Use |

ABRON PIR1800 is a reactive resin which can be thermally cured to a cross linked polyimide. This resin has been specifically designed for prepreging application and vacuum assisted resin transfer molding (lower viscosity) for structural composite applications where extended high temperature exposures are required. This resin presents a balance of excellent processability and high thermal stability. Excellent strength retention is maintained upto temperatures of ~ 3500C.

Recommended Storage Conditions :

It is recommended to store the resin at 40C and used with in 3 months of receipt. The resin can be stored for longer durations if stored at sub zero temperatures depending upon the application. Resin should be checked for specifications before usage. The resins have to be brought to room temperature (250C) before application / usage. The resin should be used within 3 days after attaining room temperature. Uncapping of the resin containers should be done only at room temperatures, as the resin is hygroscopic.

Avoid moisture contamination and contact with iron which will react with the resin. Stainless Steel containers are compatible with the resins.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Color | Yellow |

| Grade | Technical |

| Shelf Life | 1 Month At < 0 C |

| Purity | Liquid Polyimide Resin |

| Form | Liquid |

| Soluable In Water | No |

| Type | Polyimide Resin |

| Brand Name | ABRON |

| Thickness | NA |

| Style | Raw |

| Packaging Size | 0-25Kg |

| Packaging Type | Plastic Drums |

| Application | Industrial Use |

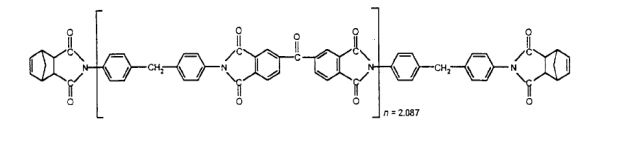

This resin offers excellent thermal stability & performance at elevated temperatures (> 400°C). The ABRON – PMR 7200 is PMR type of polyimide resin. Tg: ~ 400°C. And Curing temperature is ~ 316°C and post curing at elevated temperatures is essential.

The system is supplied as a single solution. The solid content of the resin as a single system is 70% or can be supplied as 100 % solid powder ( moulding application ). The combination of environmental friendliness, lower health risk and markedly higher use temperature makes ABRON PMR 7200 well suited for various aerospace and nonaerospace applications. Commercial applications include automotive transportation, defense, sporting goods, electronic, oil drilling, and civil engineering.

ABRON PMR 7200 exhibits high mechanical strength and structural durability at elevated temperatures. It also features significantly less moisture absorption and is therefore less susceptible to moisture induced damage. This resin demonstrates excellent thermal oxidative stability and resistance to microcracking.

The shelf life for ABRON PMR 7200 is 3 days @ 25°C, 6 months @ 0°C.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Color | Yellow |

| Grade | Industrial |

| Shelf Life | One Month When Stored At 0°c |

| Purity | Poly Amic Acid |

| Form | Liquid |

| Soluable In Water | No |

| Type | Polyimide Resin |

| Brand Name | ABRON |

| Thickness | Liquid Polyimide Resin |

| Style | Raw |

| Packaging Size | 25-50Kg |

| Packaging Type | Plastic Drums |

| Application | Industrial Use |

| Colour | Golden Yellow |

| Bulk viscosity at 25°C | 8000 - 20,000 cPs |

| Inherent viscosity | 1.5 – 3.5 dl/gm |

| Solid content | 10 – 12.5% |

| Solvent | Dimethyl Acetamide |

| Specific gravity at 25°C | 1.0 – 1.1 |

| Service temperature | -180 to +350°C |

Polyamic Acid of PMDA & ODA. High Thermal Stability upto 350 C. Used for fabrication of Polyimide Films, Wire Enamels, Anti corrosion Coatings, Spin Coating on Semiconductor Wafers, etc.

ABRON-S 10 is polyamic acid of pyromellitic dianhydride and diaminodiphenyl ether. It is a precursor used in the manufacture of polyimide insulation films. ABRON-S 10 can also be used for enameling rectangular & circular copper and aluminum wires. ABRON-S 10 is the starting material to manufacture porous polyimides and non-meltable polyimide powder (Equivalent to VESPEL® of DU-PONT).

The product made from ABRON-S 10 can withstand service temperature in the range of –180 to +350 °C.

APPLICATIONS :

- Circular & rectangular copper & aluminum wire enameling.

- Flexible PCBs.

- Polyimide Films.

- Chemical & corrosion resistant coatings.

- Porous polyimide components.